The Moccasin Bend WWTP is part of the consent decree program. The goal of which is to significantly reduce, and where possible eliminate, sanitary sewer overflows and improve the overall operations of Chattanooga’s sewer system.

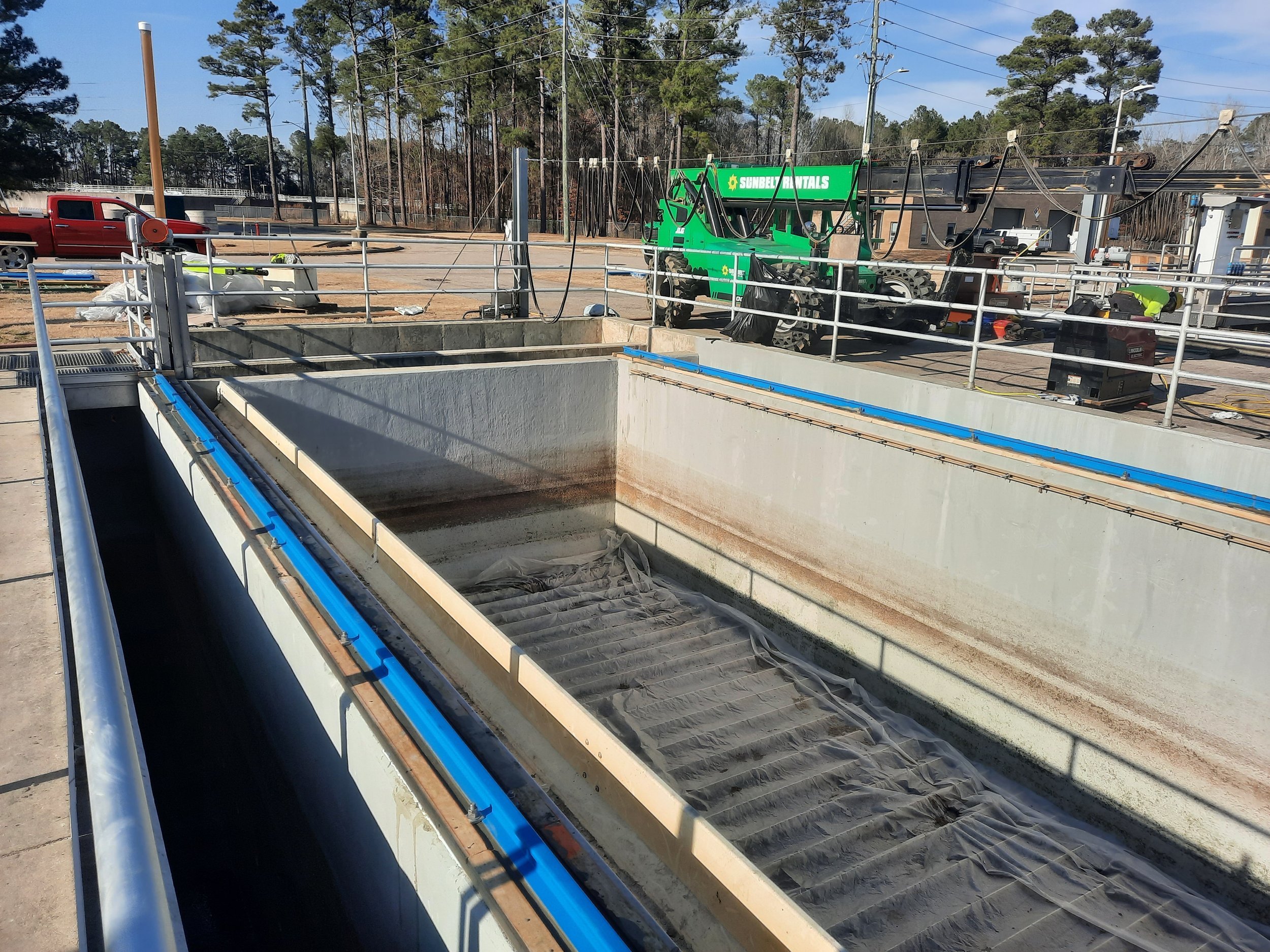

The project encompasses the demolition and upgrade of the EQ basins and blower building in facets of civil, mechanical and electrical, in addition to upgrade of other peripherals.

The existing facilities to which these improvements are being made will continue operation during the period of construction. The upgrades will be undertaken in progressive phases to ensure regular plant operations are not disrupted. These in conjunction with volatile state of material deliveries pose a unique challenge.

Project Information:

Location: Chattanooga, TN

Date Completed (Estimated): August, 2023

Contract Value of $27,685,000+

Owner: City of Chattanooga

Engineer: Jacobs

Notable Specs:

The project entails unique requirements which outline the existing facility operations and

sequencing constraints, around which the project has be undertaken

Construction of divider wall in existing EQ basins

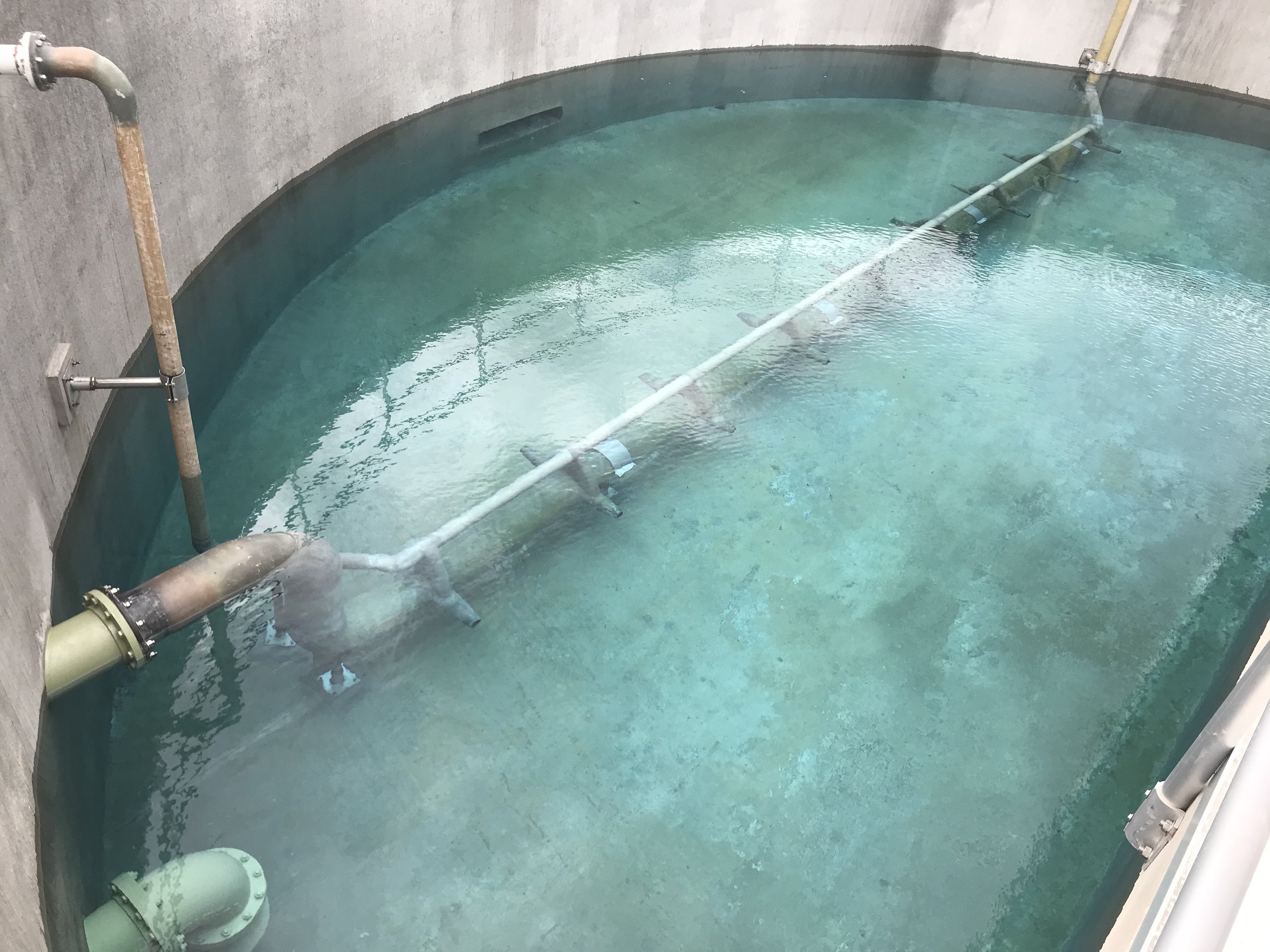

Vertical turbine pumps to feed the new water cannon system

Blower and blower building sequencing and install

Mechanical aerators to provide airless aeration