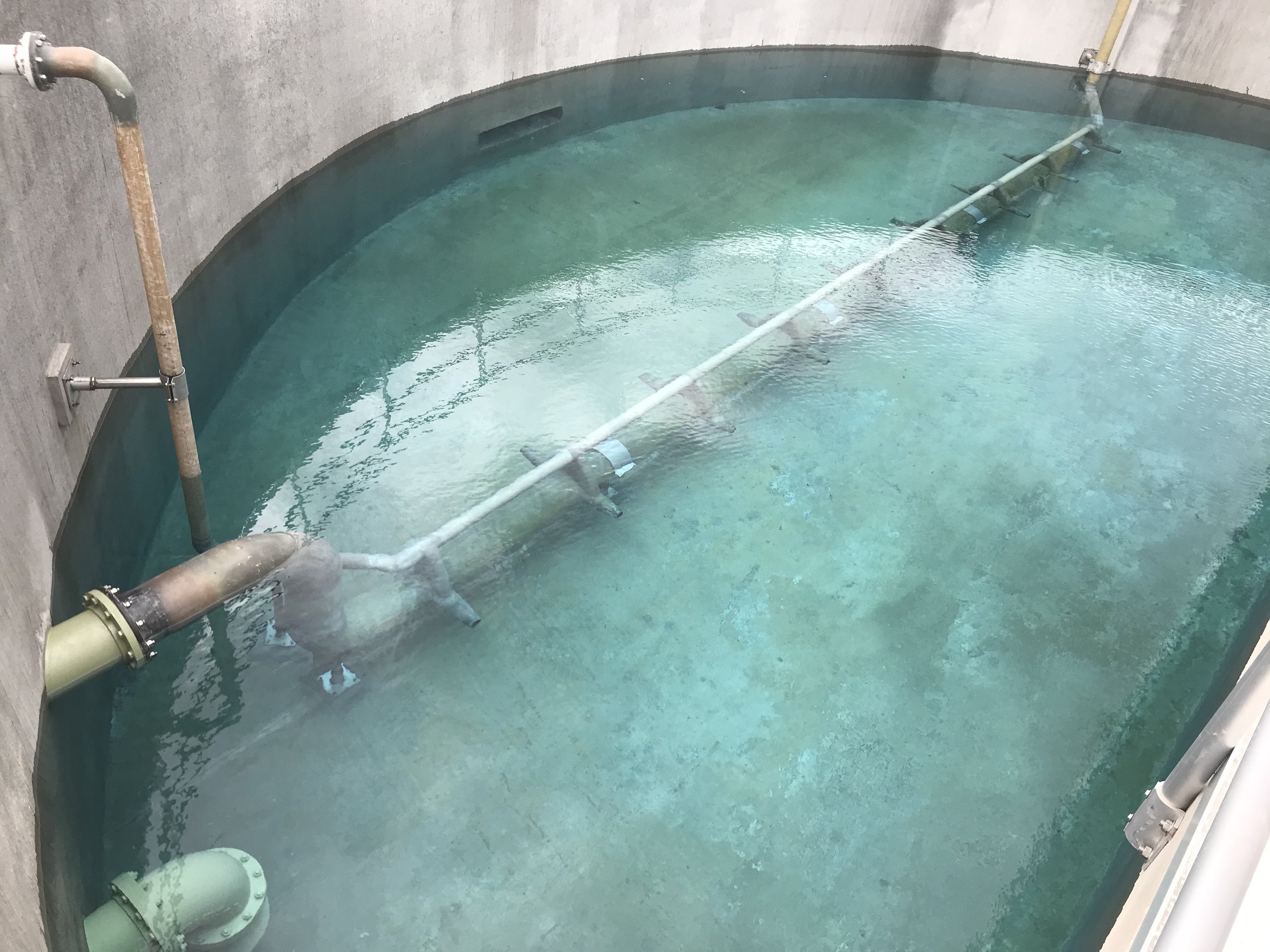

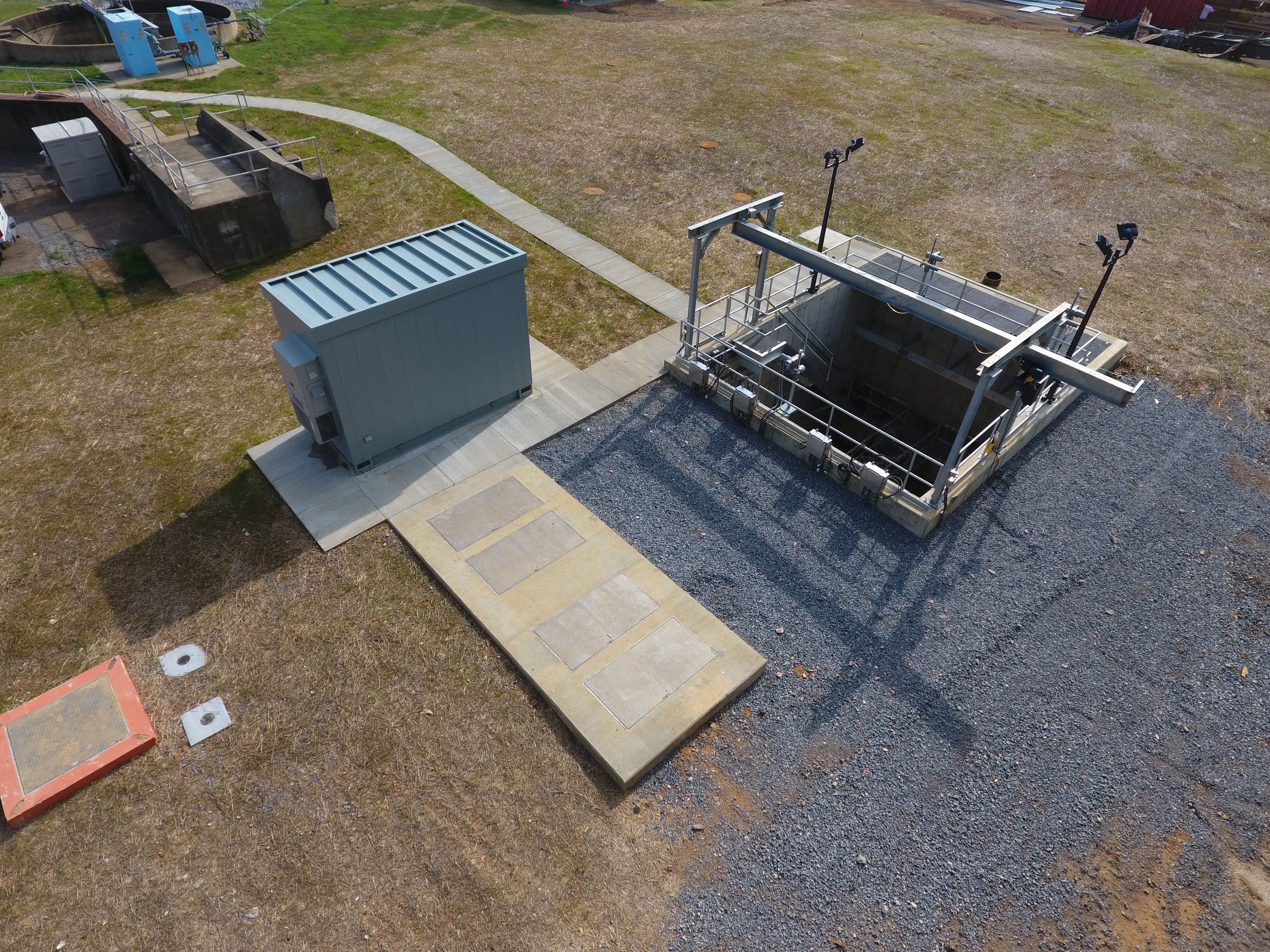

Bell and Associates Construction hired J. Cumby Construction for the rehabilitation of an existing wastewater pump station at Fall Creek Falls.

In the project, J. Cumby will be installing a new pump station access hatch, a by-pass pump around the existing pump station, new submersible pumps, new piping and a new valve vault with valves and pipes.

Additionally, J. Cumby will also be demolishing an existing sewer pump station and the existing solids storage tank, then filling it in with stone.

PROJECT INFORMATION:

Location: Fall Creek Falls, TN

Date Completed (Estimated): April, 2021

Contract Value of $250,000+

Owner: State of Tennessee

General Contractor: Bell & Associates Construction

Engineer: Barge, Cauthen, & Associates

NOTABLE SPECS:

Pump Station with a depth of 40’