Major Activities:

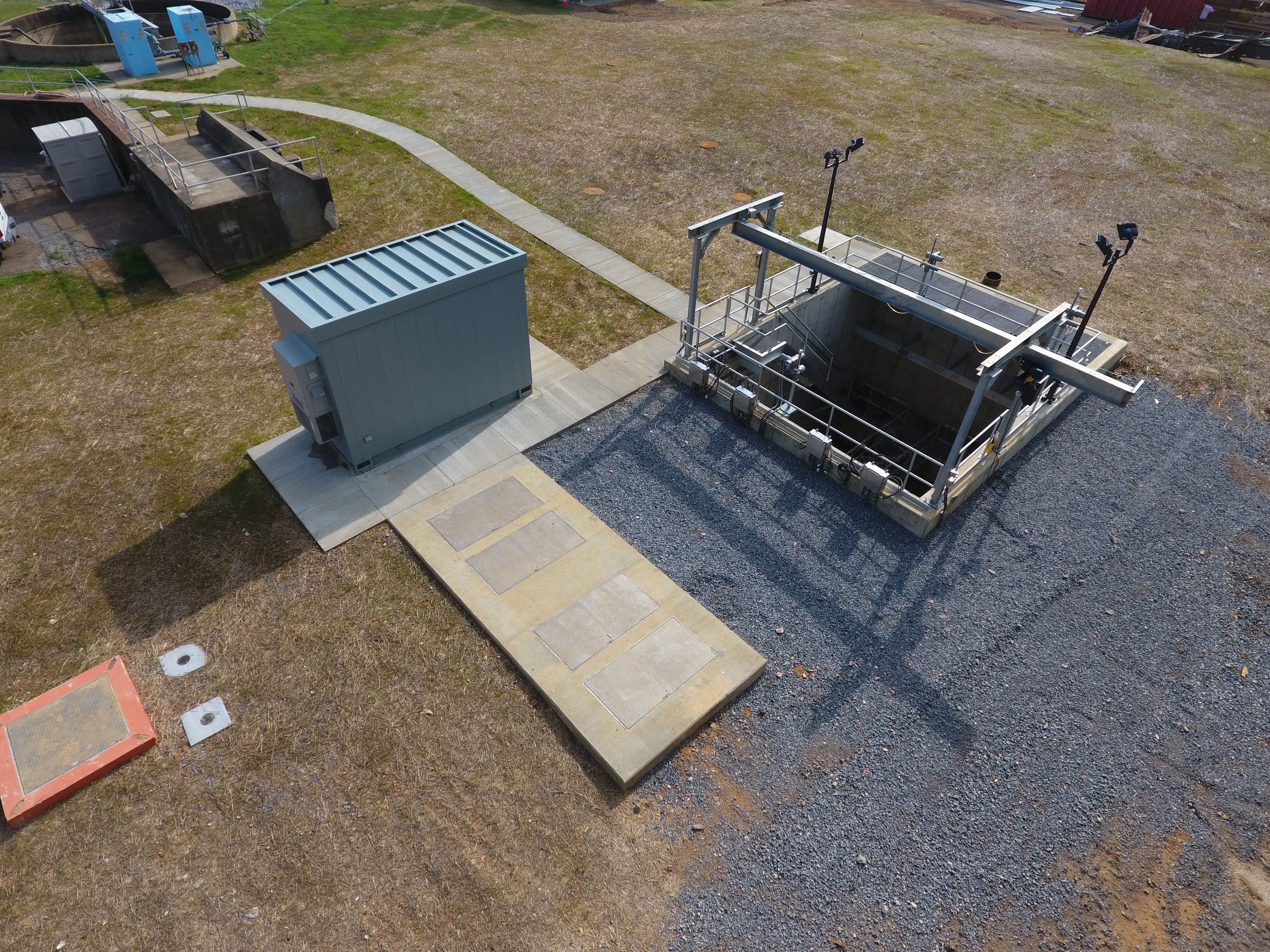

Installation of septage receiving station for offloading of septage/sludge haulers

Replacement or demolition of existing aeration basins equipment including mixers and mixer structures, diffusers, installation of a new baffle curtain system, and installation of a new blower.

PROJECT INFORMATION:

Location: Lebanon, TN

Completion Date (Estimated): November 2023

Contract Value $2,041,500

Owner: City of Lebanon Utilities District

Engineer: Water Management Services, LLC

NOTABLE SPECS:

- Maintain facility operation while dewatering and replacing equipment within (2) aeration basins during regional dry season